Satem Service, within its own workshop, carries out overhauls and repairs of turrets, slides, guides, cylinders, spindles, electrospindles and much more,

always putting professionalism and passion into work

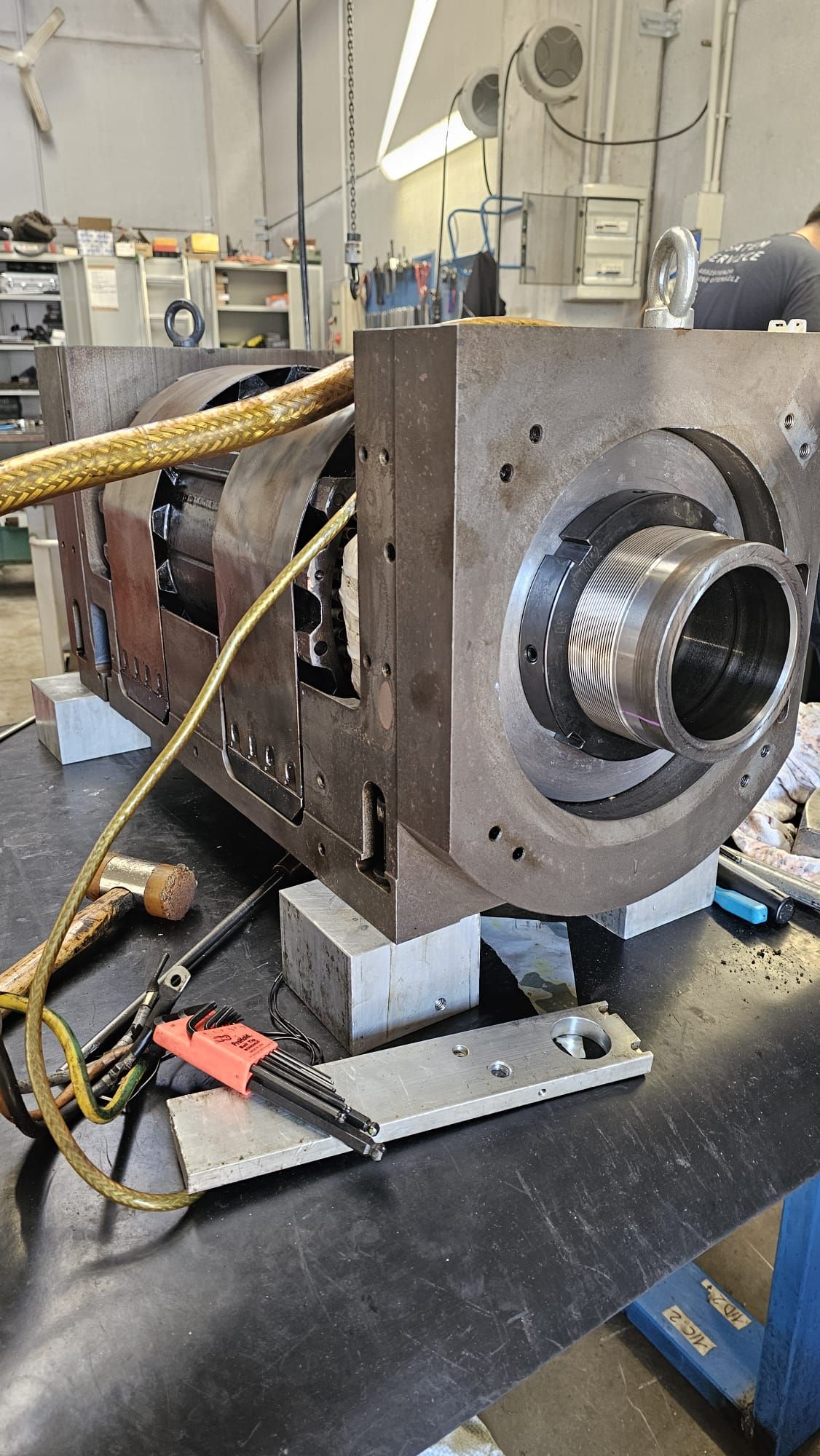

Satem Service overhauled the MORI SEIKI DMG turret

Turret overhauls restore the tool-holding system to its proper function, ensuring precision tool changes and operational reliability. Turrets, during prolonged use, can suffer from mechanical wear, play, electrical malfunctions, or jamming.

Main phases:

- Disassembly and diagnosis: opening the turret, cleaning the inside, checking the mechanical play, checking the motors and encoders.

- Component restoration: replacement of worn parts (bearings, pinions, springs, motors, seals), restoration of mechanical blocks and references.

- Turret assembly and testing: clearance adjustment, lubrication, rotation testing and tool locking.

- Reassembly: Reinstallation into the machine, automatic/manual function test.

We perform complete overhauls and repairs of DMG Mori Seiki, Duplomatic, Sauter, and Baruffaldi turrets. Toe Satem Service specializes in the overhaul of turrets for machine tools of various brands:

Doosan, DMG, Mori Seiki, Graziano, Famup, Okuma, Citizen, Biglia ... and many others: Doosan Puma TT1800SY, Doosan Puma GT2100M, Doosan Puma 700, Doosan Puma 5100MB, Doosan Puma 2600SY II, Doosan Puma 80, Doosan Puma SY 4100LB, Doosan Puma V400, WAGNER WBE, WHB, WAGNER FCQ, FCD, WMC, WAGNER WPC, WFS

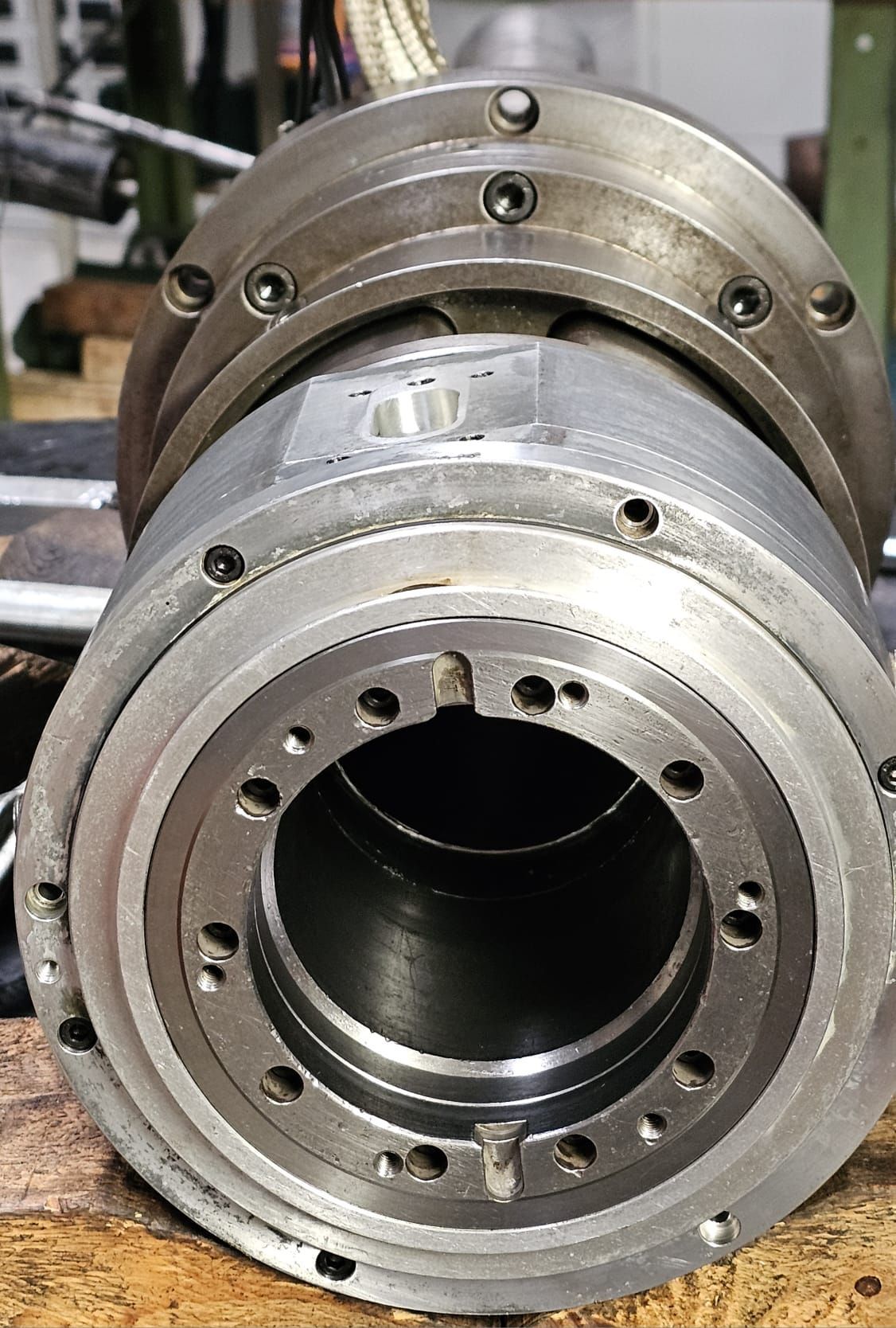

Satem Service overhauled the Autoblok cylinder

Autoblok cylinder overhauls restore the efficiency of the spindle clamping system, ensuring clamping force, hydraulic seal, and machining safety. Autoblok hydraulic cylinders are widely used in CNC lathes from major brands for automatic spindle clamping. They are installed on models from Doosan, DMG, Mori Seiki, Graziano, Biglia, Okuma, Victor, and many others.

Main phases:

- Disassembly and diagnosis: opening the cylinder, internal cleaning, checking for seals, checking the sliding surfaces, inspecting the piston and gaskets. - Component repair: replacing gaskets, scrapers, oil seals, O-rings, and damaged components; mechanical inspection of the cylinder body. - Assembly and testing: reassembly with adjustments, pressure testing, checking for hydraulic seals and piston movement.

Satem Service offers Autoblok cylinder repair and overhaul services for machine tools: Doosan, Biglia, Citizen, DMG, Kitamura, Fagima, Victor, Mori Seiki, Daewoo, Graziano, Gildemeister, Stama, Deckel Maho, Okuma specifically Doosan (Puma 2600, 3100, 5100, 700, GT2600, TT1300), Graziano (MT 500, CTX 700, GR 500C), DMG/Gildemeister (CTX 410, 420, 510, Twin 65).

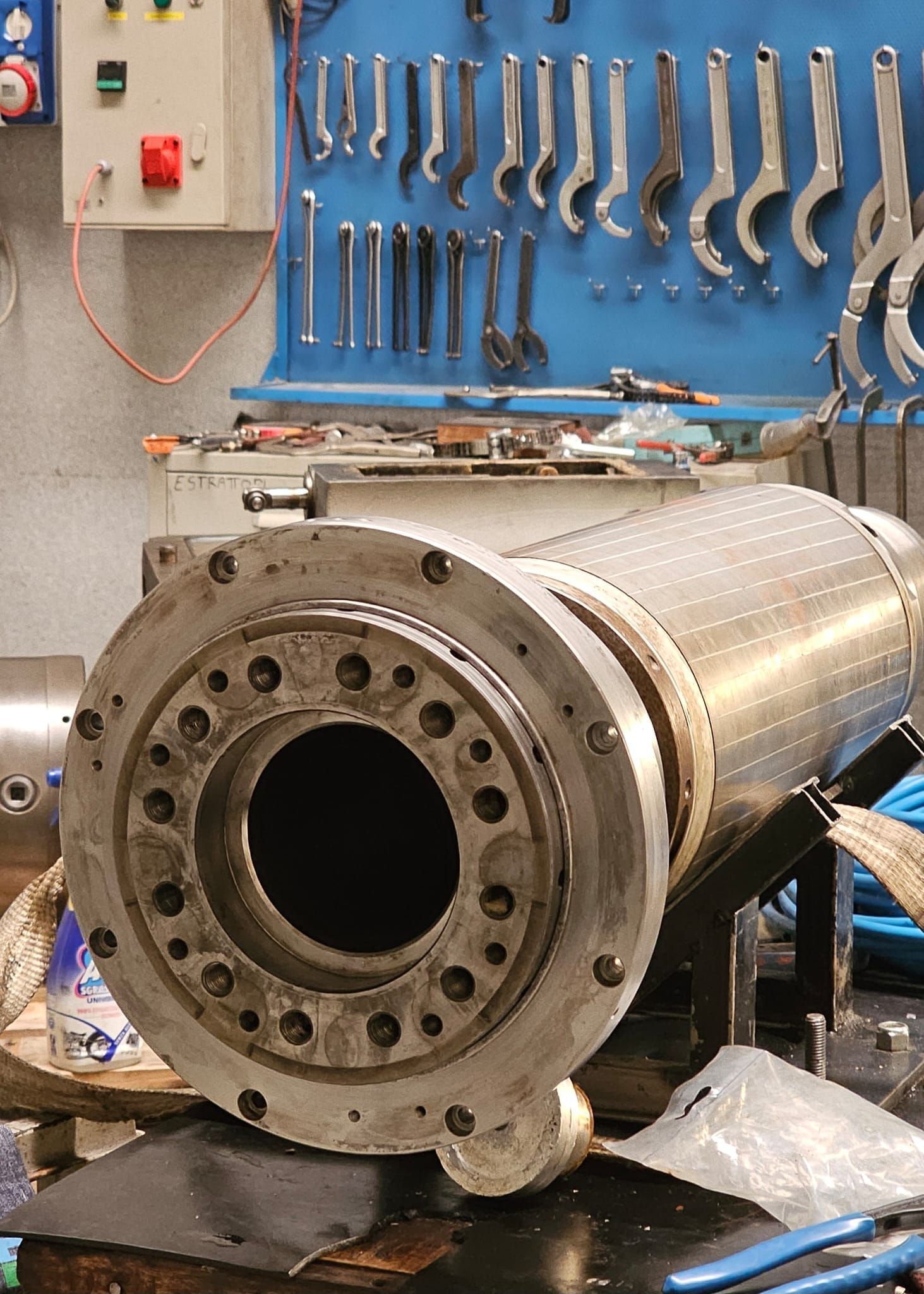

Satem Service overhauled the ELECTROSPINDLE of the CTX 410 DMG lathe.

Spindle head repair restores precision, stability, and reliability. Heads, used to rotate the spindle and workpiece, are subject to mechanical wear, vibration, overheating, and loss of concentricity over time.

Main phases:

- Disassembly and diagnosis: cleaning, visual inspection, play check, mechanical and electrical tests on the electrospindle, bearings, and encoder. - Component restoration: precision bearing replacement, spindle shaft inspection, seal check, lubrication, dynamic balancing if necessary. - Assembly and testing: reassembly with adjustments, bench test with vibration, temperature, absorption, and noise verification. - Reassembly: reinstallation in the machine with final concentricity and performance check. We perform maintenance and overhauls on spindles and electrospindles on various machine tool models, especially DMG Gildemeister lathes, including: DMG CTX 200 E, CTX 310, DMG CTX 400, DMG CTX 420, Mt500 Maho Graziano, Mt400 Maho Graziano, Gr300 Maho Graziano, DMG CTX310 Graziano, DMG CTX500 Graziano, Biglia B-565-YS, Doosan Puma TT1800SY, Doosan Puma GT2100M, Doosan Puma 700, Doosan Puma 2600SY, Doosan Puma V400, and many others.

Satem Service overhauled the SAUTER turret

of the MT 400 GRAZIANO lathe

The Sauter turret overhaul serves to restore the correct functioning of the tool holder system, ensuring precision in tool changes and maximum operational reliability.

Main phases:

- Disassembly and diagnosis: opening the turret, cleaning, checking clearances, checking the motors, encoders and limit switches.

- Component restoration: replacement of worn parts (bearings, pinions, springs, seals), checking locking and mechanical references.

- Assembly and testing: clearance adjustment, lubrication and tool rotation and locking tests.

- Reassembly: reinstallation on the machine and automatic and manual functional test.

Satem Service offers specialized turret overhaul and repair services for machine tools of the main brands DMG, Gildemeister CTV 160, CTV 200, CTX 410, CTX 420, DMG Gildemeister Twin 65, Graziano GR 500C, Graziano CTX‑300, Graziano CTX‑400, Graziano CTX‑500, Graziano MT‑400C, Graziano GT‑400, Graziano GR‑350C, Graziano GR‑400C

Electrospindle overhauls

Satem Service has carried out repairs on a DMG SPINDLE HEAD

The spindle head overhaul aims to restore precision, stability, and reliability in CNC machine tool machining.

Main steps of spindle head repair:

- Disassembly and diagnosis: cleaning, play check, testing of the electrospindle, bearings, and encoder. - Component repair: bearing replacement, shaft inspection, seal inspection, lubrication, balancing. - Assembly and testing: reassembly, vibration, temperature, and absorption testing. - Reassembly: installing the electrospindle in the machine and checking concentricity.

We carry out repairs of electrospindles and spindles of various models of Okuma, Kitamura, Citizen, Biglia, Hermle, Stama machine tool lathes in particular: Doosan Puma 600, Doosan Puma GT2600, Doosan Puma TT1300, Doosan Puma DNT2600, Puma 3100, Doosan Puma 4100, Wagner WDS 520/A, WDS 560/A, Wagner WDS 600, AYMori Seiki SL-15, Mori Seiki SL-20, Mori Seiki SL-30, Mori Seiki SL-40, DMG Gildemeister CTX 410 and many others.

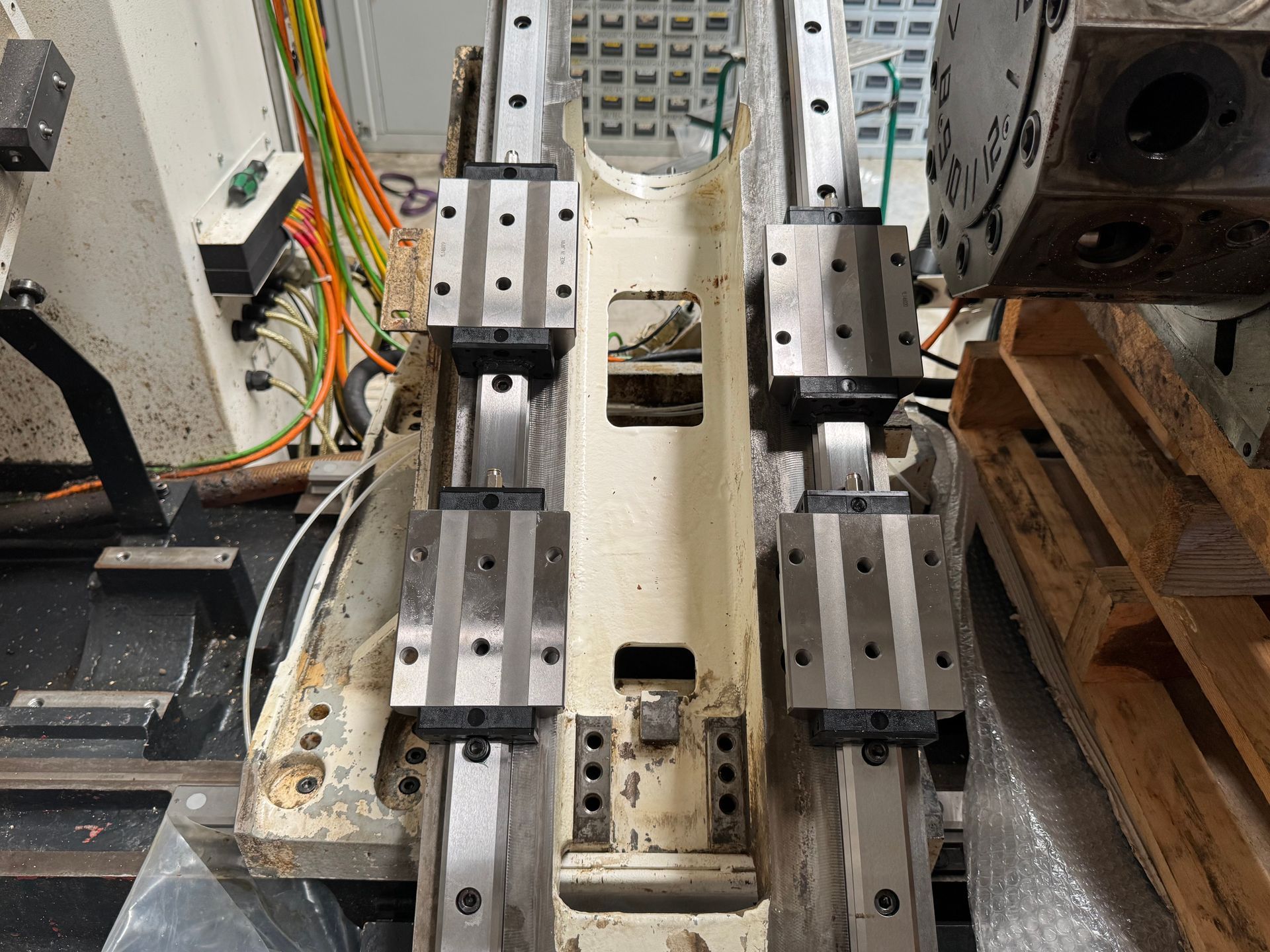

Overhaul of guides and slides for machine tools, lathes and milling machines

Satem Service overhauled the guides and slides of the Mazak Quick Turn Nexus 200-II MS lathe.

Overhauling guides and runner blocks restores the sliding precision of the axes and ensures stable movement. During operation, linear guides and recirculating ball bearing runner blocks can experience wear, play, and loss of lubrication.

Main phases:

- Disassembly and diagnosis: removal of the crankcase, cleaning of the guides and pads, checking the state of wear.

- Component restoration: replacement of damaged pads, checking and grinding of guides if necessary, cleaning and surface treatment.

- Assembly and testing: lubrication, clearance adjustment, axis sliding check.

- Reassembly: crankcase assembly, final testing on machine tool.

Among the brands we operate on: Mazak Quick Turn Nexus 100-II MSY, Mazak Quick Turn Nexus 250M, Mazak Quick Turn Smart 350, Doosan Puma 2700, Doosan Puma 2600SY, Doosan Puma 3100, Doosan Puma 4100, Mori Seiki SL-15, Mori Seiki SL-20, Mori Seiki SL-25, Mori Seiki SL-30, Mori Seiki SL-35, Mori Seiki SL-40, Gildemeister CTX 410, DMG CTX 410 3 Axis and many others.